Hotline

Hotline400-101-4540

Hotline

Hotline

Gas supply service mode (BOT)

Gas supply service mode (BOT)

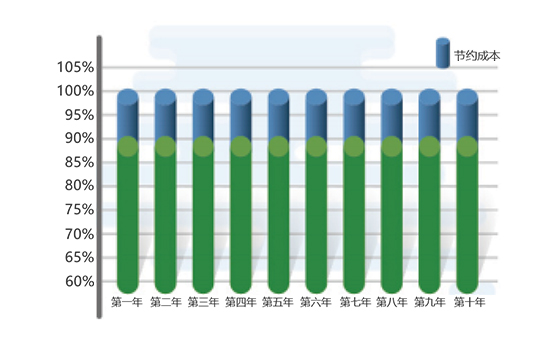

In the compressed air field, based on the BOT mode of lean management, the energy company implements all-round operation hosting services for the user's compressed air system, and undertakes all-round services such as investment, construction, operation and maintenance of the user's compressed air system,

While reducing the user's gas consumption cost, continue to carry out energy-saving upgrading to recover the project investment and reasonable profits. After the expiration of the contract, the assets of the air compressor station will be handed over to the customer free of charge

![]() Gas demand 100 m ³/ Min, pressure demand 7 bar, gas quality demand, dew point 2-10 degrees

Gas demand 100 m ³/ Min, pressure demand 7 bar, gas quality demand, dew point 2-10 degrees

![]() According to the current comprehensive gas consumption cost of 0.1 yuan / M ³, The startup time is 8000h, the electricity price is 0.7 yuan / kWh, and the total annual expenditure is 4.8 million yuan

According to the current comprehensive gas consumption cost of 0.1 yuan / M ³, The startup time is 8000h, the electricity price is 0.7 yuan / kWh, and the total annual expenditure is 4.8 million yuan

![]() The gas supply service (BOT) mode is adopted, and our company invests, constructs and undertakes the electricity charge and operation management. The comprehensive gas quotation decreases by 5% - 10%, saving 480000 yuan per year

The gas supply service (BOT) mode is adopted, and our company invests, constructs and undertakes the electricity charge and operation management. The comprehensive gas quotation decreases by 5% - 10%, saving 480000 yuan per year

![]() After the end of the contract, the property right of the equipment will be handed over to the user, and our company will ensure that the gas cost will be reduced by 5% - 10%

After the end of the contract, the property right of the equipment will be handed over to the user, and our company will ensure that the gas cost will be reduced by 5% - 10%

Energy saving concept

Energy saving concept

01

Gas producing side

The use of high-efficiency customized centrifuge, two-stage compression screw machine, permanent magnet frequency conversion technology, station building intelligent group control system and energy efficiency management system can realize the pressure constant pressure operation of the station building, change the problem of large pressure fluctuation in the loading and unloading operation of the traditional air compressor, improve the operation efficiency and reduce the operation cost

02

Conveying side

According to the actual gas quality requirements of users, energy-saving frequency conversion double compression refrigeration dryer, zero gas consumption adsorption dryer, energy-saving low-pressure differential filter and station room pipe network optimization are customized, and super pipeline and smart valve are used to reduce the pressure loss and leakage flow loss at the transmission end and reduce the energy consumption loss of comprehensive gas transmission

03

Gas side

According to different process requirements, supply by quality and pressure, adopt terminal energy-saving management means, process upgrading and transformation, use of energy-saving nozzle, application of throttling technology and application of pressure reduction technology

04

lean management

Data collection and platform analysis are carried out in the whole process to realize intelligent and intelligent operation. Online and offline are combined to reduce the comprehensive gas consumption cost through lean management

Lean management services

Lean management services

Compressed air LCC cost

Compressed air LCC cost

Investment cost

Accounting for 5% (construction cost of air compressor station, including auxiliary system)

Energy consumption cost

Accounting for 80% (electricity expenditure of air compressor station, including post-treatment, cooling water system, etc.)

Operation and maintenance cost

Accounting for 10% (air compressor station repair, maintenance, overhaul, operation and maintenance management, etc.)

administration cost

Accounting for 2% (management personnel, daily management expenses, etc.)

Capital cost

Accounting for 3% (the capital cost of air compressor station construction is calculated at 8%)

Case sharing

Case sharing