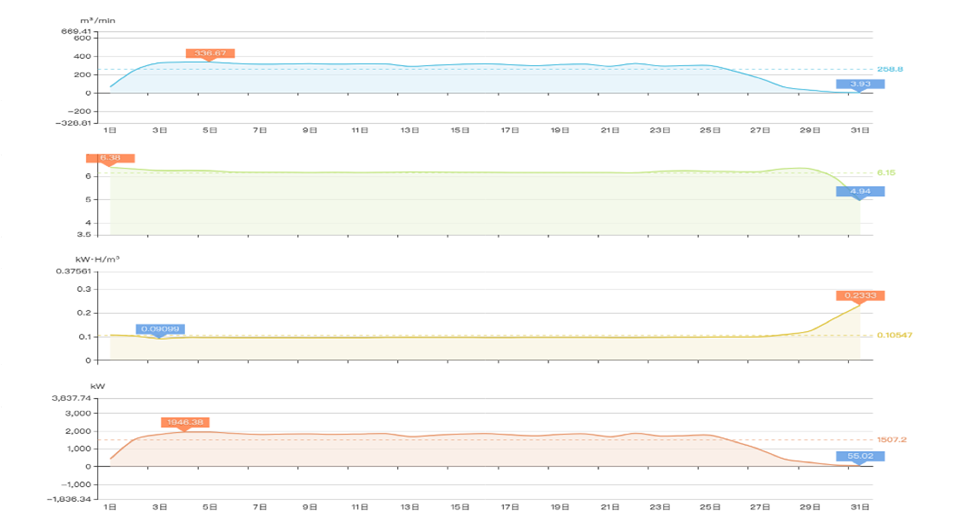

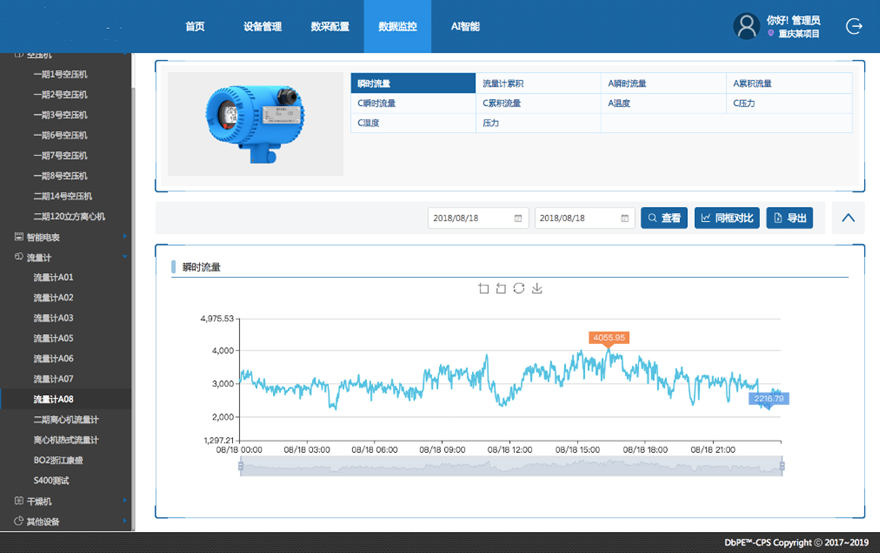

Minute level management

Based on high-speed and effective data acquisition, cloud real-time storage, scientific and reasonable calculation, the real-time unit consumption per minute is used to benchmark the operation energy efficiency of the whole station, so as to ensure that the compressed air system is always in an efficient operation state.

400-101-4540

Hotline

Hotline

Location:

Location: Development of high cost performance air compressor for excellent gas Depot

Development of high cost performance air compressor for excellent gas Depot